Our mission: To source as many masks as possible

Leveraging our manufacturing partners, we have the capacity to source 200,000 masks per day

By: Wendle Whiting, Amatis Manufacturing Manager

We can help get medical-grade masks to frontline workers and need your help spreading the word, buying masks, or donating to the cause.

Buy or fund masksThe Covid-19 pandemic is an unparalleled challenge that the world must work together to solve. As the virus spreads around the planet, different regions will take turns confronting the bulk of the new infections. Right now it is America’s turn.

The best way we know how to fight back, right now, is to slow the spread of the virus until an effective treatment, vaccine, or cure can be found. The lives of those who may not survive if infected are in all our (well washed) hands.

The suppression of the outbreak in China was in no small way aided by the habit of many Asian cultures to wear masks in public when they are ill, and it was easy to switch from ‘occasionally’ to ‘all the time,’ even if they felt healthy. By wearing masks, the chance of an asymptomatic person spreading the infection is greatly diminished by reducing the aerosolization of the tiny virus exiting the mouth. If everyone wore a mask all the time, we would see a drastic decrease in the velocity of new infections.

In the United States (U.S.), we don’t have the culture of wearing masks in public places, which has made the speed of the spread very fast in our country. We are aided by stay-at-home directives, as long as they are followed, but we are only just now starting to find normality in seeing masks when we venture to the grocery store. This is a good thing; we are going to have to do it for a while.

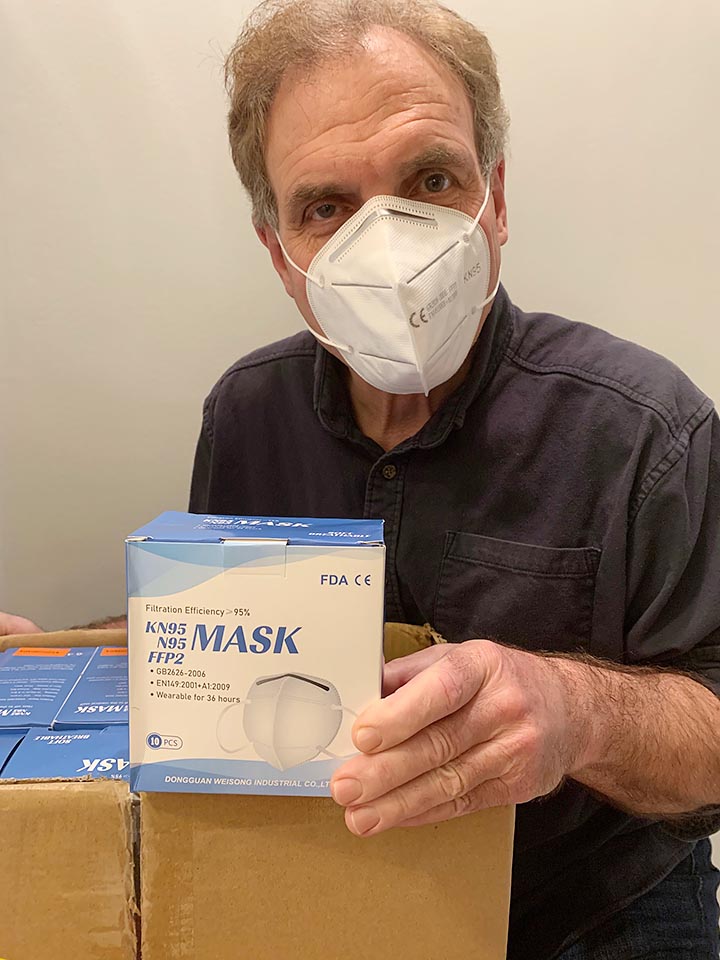

(Left) Grosse Pointe Rotary Sunrise Club former president Bob Duker examines a mask shipment. The rotary has partnered with Amatis to fundraise and distribute masks to Detroit area hospitals and medical facilities.

(Right) Amatis’ Wendle Whiting (far right) partnered with Matt Hecht to distribute masks to the Pitkin County Jail in Colorado.

Why masks matter

It’s one thing for a person who may have the virus, but not know it, to wear a scarf, buff or other covering over their face to protect those around them. It is relatively easy to intercept the virus just after it has just exited the mouth of an infected person; the virus is concentrated into a small space and is generally stuck together with bits of the moisture that accompanies a sneeze or cough. This works much better than nothing and is a huge help towards slowing the spread of the virus.

It is an altogether different thing for a healthy person to try to protect themselves from contracting the virus by using something that isn’t meant to filter all the air they are breathing in. A mask made to protect a healthy person from contracting an airborne pathogen is designed to closely fit the face in order to force all of the air a person is breathing in to pass through a material that specifically impedes the path of a particle as small as a virus from easily entering the lungs. These types of masks are called N95 in America (KN95 in China). These are the masks that an essential worker must wear in order to reduce the risk of contracting something from those around them. In the case of our front line health care workers during this crisis, it is crucial. We need them to stay healthy so they can save our lives.

Unfortunately, in the regions of our country where the virus is currently causing health care facilities to overflow, and the need for protective masks is greatest, there are few to go around. Brave, courageous, but frightened workers place themselves in danger to care for their fellow citizens in their greatest time of need.

The U.S. was caught unprepared to supply the volume of necessary personal protective equipment (PPE) to those who need it the most. China, understandably, stopped exporting masks during their time of crisis, and the U.S. does not have the manufacturing capacity to fully meet our own demand.

Fortunately China, the world’s manufacturing hub, has managed to slow the spread of their outbreak enough to again allow export of the masks necessary to help protect the healthy among our essential workers.

If it was only a simple matter of directing all mask exports directly to America, we wouldn’t be writing this blog post. There are several obstacles to scaling up the supply chain to get masks to those we need to have them.

-

- As demand for masks skyrockets worldwide, even the significant manufacturing capacity of China is not even close to being able to meet demand. Building additional production takes a lot of time, unless;

- Companies who have no experience or skill in manufacturing decide they want in on the action and begin haphazardly making and shipping masks that are ineffective for the use they are being marketed as, therefore;

- Low quality, unregulated masks made in China began to enter the American market and both the USA and Chinese regulatory bodies had to take action, resulting in;

- The customs agencies of both countries severely restricted the export/import of masks in order to prevent ineffective masks from, in China’s case, further damaging their reputation during this crisis, and in the U.S.’s case, being used in environments where their efficacy is critical. Consequently;

- Chinese customs is now inspecting 100% of mask exports to verify that they are, indeed, made by manufacturers who have been, and are still, continuously inspected and certified to make the type of masks they are selling, and;

- USA customs is checking to make sure that imported masks either have received FDA certification, or the manufacturer has been given a specific exemption for the type of mask and uses they are intended for. This causes;

- Delays in exporting masks from China as their customs agents are inundated by huge shipments of masks. Exports are now being “pulsed” through customs, with shipping companies being ordered to not pick up shipments of masks from manufacturers for a few days at a time so that customs is able to catch up with their inspections. But even once they are through they are again further delayed by;

- A lack of air freight capacity. Prior to this pandemic, the majority of air freight between China and the USA was carried in the bellies of passenger aircraft. All of that capacity has evaporated along with commercial flights between the countries. The major freight carriers do not have the ability to make up all of that lost capacity very quickly. This has caused the freight companies to limit the amount of any single shipment between manufacturers and importers to a certain size or weight. And it is not just America that needs masks;

- The demand for masks is coming from the entire population of the earth. As the demand increases as the virus spread around the planet the entire production capacity of China will not be enough to meet the demand, consequently lead times will increase, sooner rather than later the lead times will become so long that it won’t make sense to even attempt to import them, meanwhile;

- Profiteers are unconscionably taking advantage of the supply/demand imbalance to sell masks for outrageous prices, which hurts all of society.

Summary: Masks are difficult to source, supply can’t grow quickly, demand and prices are soaring, and shipping is delayed by logistics issues.

All of these factors are challenges that are contributing to the shortages of masks that we see health care workers and essential workers pleading for all over social media, the news, and in person.

Where does Amatis Controls fit into this?

We are a lighting controls company, true, but we are a lighting controls company whose products are made in Shenzhen, China. For almost a decade we have been there establishing relationships with our manufacturing partners. Conducting business in China is a difficult and delicate process. There are some (lots of) elements of truth to the reputation of manufacturing in China. It takes a long time, and a lot of work, to develop the relationships, systems, processes, and trust that are needed to have anything made in China. It doesn’t matter if it’s an iPhone, a sensor, a charging cable, a toy, or a mask: if you don’t have a continuous personal relationship with the manufacturer you likely won’t get something that you can be proud of selling.

During the beginning of the pandemic, our manufacturing partners were closed while they learned how to fight the virus. Now that they have it, seemingly, under control, our partners are open and ready to share with us what they’ve learned and have been compassionate towards us now that the shoe is on the other foot.

One of our manufacturers has invested in mask manufacturing capability in partnership with a legacy mask-making company in order to obtain the skills, knowledge, and equipment to properly make (K)N95 masks. While it will take months for their own line to begin production, they now have direct access to the supply from a company that has been making medical and surgical masks for the Chinese market for many years. The masks have always been KN95 certified, and are now FDA certified as well.

While Amatis Controls is affected by the economic slowdown, we have chosen to put our experience of working with China towards making a difference where we feel we can make the most impact.

Our employees have joined together with their time and skills to help get masks where they are needed most. We have set up a project for this purpose.

Our Mission: To source as many masks as possible, as quickly as possible, before lead times increase to unreasonable lengths, and facilitate the distribution of the masks to those who are in most need.

To begin the project we started with a modest fund of $10,000 in donations by employees. We then bought masks with that money to begin learning what we would need to know in order to navigate the anticipated quirks and obstacles that always arise when working with Chinese manufacturers and customs agencies.

Our intent is to leverage that $10,000 in seed money by selling the masks with a mark-up that will enable us to replace the masks purchased, but also increase the fund which is then used to buy even more masks. We are not doing this for profit. Net proceeds are going back into that fund to purchase more masks. In this manner we hope to increase our small fund into a larger fund, which allows us to order more masks more quickly as soon as possible. It is inevitable that lead times will increase drastically, so time is of the essence in order to make a difference. By selling the masks well below the cost that profiteers are selling them for we hope to get more masks to essential workers who have no choice but to buy their own PPE but have difficulty finding and affording them, and to first responder and health organizations that are running out of funds for PPE while being extorted by unethical middle-men.

This project is working already. We have distributed 3,208 masks, we have ordered 15,333 masks, and our fund is now at $16,898. Our first large shipment of masks that was subjected to all the new customs regulations has now passed both Chinese and US customs agencies and will be here Thursday.

We have proven it can be done.

Now we want to prove we can make a difference.

We are taking orders for as few as 20 masks, and have the capacity to source 200,000 masks per day!

What we need is you to spread the word, buy masks for yourself, buy masks for others, donate money.

While no purchase or donation is too small, and a single mask is a success story if it prevents one essential worker from being harmed, the biggest difference is going to be affected by significantly increasing our buying power early on, before it takes months to get a meaningful amount of masks through the increasingly bogged down system.

We need benefactors who want to target a specific region with a large purchase of masks to the organization of their choice.

We need friends and families to buy masks for their loved ones, or to give masks to their grocery store workers, bank tellers, bus drivers, and those who are essential workers but without any access to effective protection.

We need philanthropists willing to make significant donations or purchases to help leverage the fund’s buying power early on.

If we had a fund with hundreds of thousands of dollars we could set up an ordering and delivery cadence that would allow us to have a constant stock of masks in our facility so that we could ship orders out immediately and at low cost. We appreciate the patience of our early purchasers and funders who are still waiting for their deliveries. We are catching up and hope to be able to fill all existing orders very soon. If we can increase our fund significantly, we will be able to have masks on stock, instead of placing orders with the manufacturers only once the purchase and donation money has arrived. Which causes a significant delay.

We need people with big hearts and wallets to purchase enough masks to make a significant impact on the people who are risking their lives to help us, our families and friends.